If you’ve ever been involved in the construction or metal fabrication trades, you might have noticed units of measurement seeming to arbitrarily switch between one material and another.

At least in the UK, aluminium is ordered and measured in imperial units: inches and feet, while steel is ordered and measured in the conventional metric: millimetres, centimetres, metres. But why is that? To find the answer, first we must explore and compare the histories of these two metals.

The history of aluminium is a short but fascinating one. Though first theorised about, and thus named, in 1808, pure aluminium would not be produced out of aluminium oxide until 1845, by a German chemist named Friederich Woelher. The metal was expensive to create at the time, lightweight, and resembled silver, and so aluminium’s first applications were luxury; ornamental. The first notable use is sometimes considered to be as medals produced during the reign of Napoleon the third. Aluminium would not stay ornamental for long, however. A more cost-efficient method was developed in 1885 by a French engineer and American student pair. The engineer, Paul Héroult, set up a smelter using this new method in Newhausen, Switzerland. Importantly, the American, Charles Martin Hall, took the method back with him to the States. He established what would become the Aluminium Company of America (known today as Alcoa) and in just under ten years, the company had three smelting sites, and became the only legal supplier of aluminium in the United States. Though the rest of the world would soon catch up, it is notable that this was the origin of the first real aluminium industry.

Early industrial uses of the metal included passenger boats, as components of sports cars, and as specialised parts in torpedo boats. Perhaps most critically, it was aluminium’s lightweight properties that prompted its use by Wilber and Orville Wright in their prototypal aeroplane, Flyer-1. Aluminium went on to gain the nickname ‘winged metal’, in reference to its, and its alloy, duralium’s, importance in the field of aviation.

Aluminium gained major places in the utensils and food packaging industries, as well as being integrated into a major construction for the first time with the erecting of the empire state building in 1931.

Mirroring its instrumental place in kickstarting the aviation sector, aluminium would be elemental in our exploration into space. The first satellite launched into space would made primarily of the winged metal, while all subsequent spacecraft necessitated its incorporation. Back on earth, aluminium was also making high speed train travel possible.

The 2008 global financial crisis resulted in a drastic closure of many western aluminium companies. Today, the top global producers of aluminium are, in order, China, India, and then Russia

By comparison, the history of steel is much more massive and long stretching. While aluminium is relatively new, humanities relationship with steel and its precursor iron alloys, stretches back to before the historiographical record began.

Iron smelting itself could possibly be dated as far back as the third millennium BC. However, wrought iron, a low carbon alloy and forerunner to steel, did not become common until the 12th century BC. Around 500BC, cast iron was invented by Chinese metalworkers. It wasn’t until 100 years later, on the Indian subcontinent, that true steel would be developed for the first time. Their approach came to be known as the crucible method, and steel was traded around Asia and Europe.

Following the fall of the Roman empire, it became nearly impossible to ship to Europe, and steel fell out of use on the continent, though it was still produced across Asia for centuries. Not knowing how to make steel, Europeans perfected iron smelting over that time, substituting charcoal for roasted coal.

The breakthrough came from an English clockmaker, who found iron insufficient for his delicate work. Combining the crucible method with the utilisation of roasted coal let him develop a method that resulted in higher quality steel than ever before. Infrastructure produced from the resultant steelworks included steam engines, water fountains and lampposts.

Two developments in 1856 and 1886 made it possible to produce steel cheaply, quickly, and in larger quantities. In the Americas, the steel industry became more focused on roads, bridges and railways, eventually aiming itself towards skyscrapers. The included use in the Empire State Building, which along with aluminium, utilised 60,000 tonnes of steel.

Much of the global steel industry was completely consumed by the onset of WWII, as it was needed for ships, guns, tanks and planes.

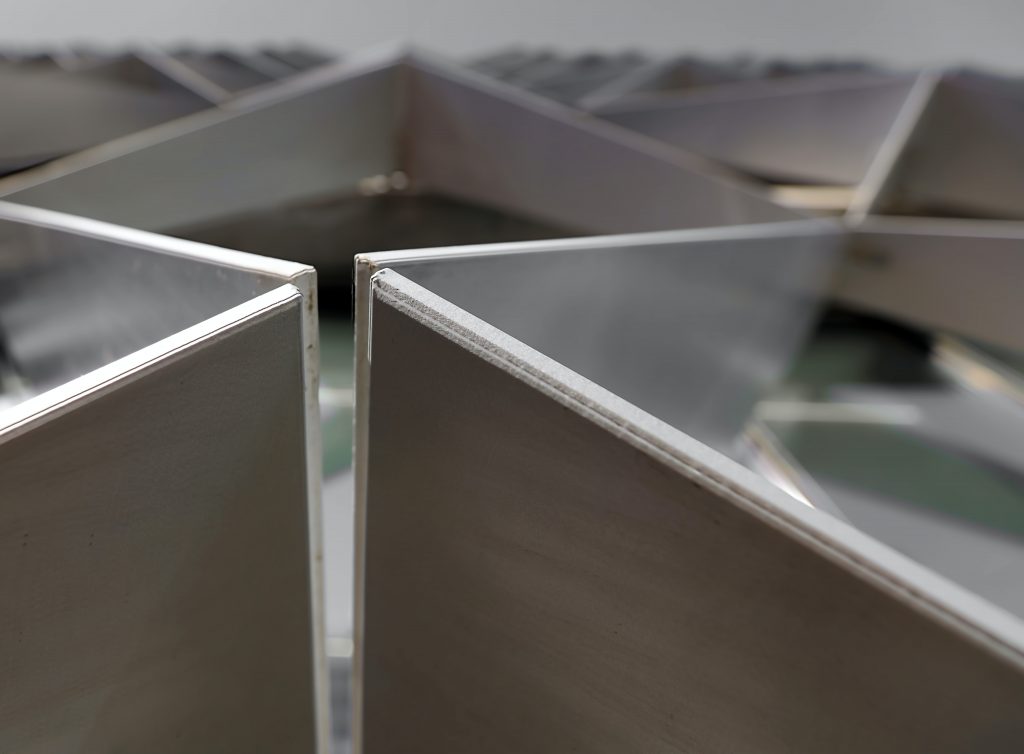

New, even more efficient and cheaper methods of steel production were discovered at the turn of the 20th Century, and in 1912 a steel-chromium alloy was invented that became known as stainless steel. Stainless steel quickly gained use as pocketknives, surgical tools, and cutlery. In the 1950s, the steel production industries took a hit from a cheaper metal: aluminium.

The USA fell from the top spot of the worlds steel producers back in the 1970s. Today, the top global producers are China, followed by the European Union, and then India.

From here, we can extrapolate why aluminium producers use the imperial system, while steel favours the metric. Steels longer history, it’s much more varied roots, place it historically with the wider global community and its preference for the metric system.

Meanwhile, aluminium has a shorter history, the metal only really taking off as an industrial product once Charles Hall brought it back with him to the USA. Young enough to have matured in America, aluminium’s most notable uses (aviation, aerospace engineering, and the canned drink industry) all originate in the States, which is the only country to favour imperial measurements. Despite production branching off towards other nations, aluminium is still linked back to its country of origin by this custom.

Even so, this is only convention. Either metal can be measured with either unit, and many manufactures chose to eschew this practice in favour of choosing one or the other, for consistencies sake. Still, it’s interesting to know why this distinction is made, and the marks that history leaves in the building blocks of our most basic materials.