Cantilevered Bespoke work platform – Excent UK:

Quality

Aircraft maintenance platforms are aviation access systems designed to give engineers safe entry to areas of an aircraft that require repair, maintenance or installation. Platforms will be of varying shapes, height and sizes, some multi-level and mobile.

We work closely with clients to design, develop and install high quality bespoke aircraft maintenance platforms and equipment with the best quality materials to meet their needs. Our key aims are quality, simplicity, safety and efficiency.

Design

In-house designers work with the client to develop a safe bespoke aviation platform to their needs and provide a solution to their problems.

Designs are modelled using solid works 3d software to match the profile of the aircraft this ensures all the needs of the engineers are met to achieve the best aviation platform.

The equipment is made to all relevant regulations and an independent engineers will perform calculations to ensure the platforms are fit for purpose and meet to the latest regulations.

Operations

Bespoke aircraft maintenance platforms are designed to help give access to key parts of the aircraft focussing on safe and efficient use whist ensuring safely working at height.

Aircraft maintenance platforms include to:-

- Tail dock systems

- Wing access

- Cargo and passenger door Access

- Under wing

- Engine cowling

- Nose

- Wheel well

Working at height and safety

Aircraft maintenance platforms are individually designed to ensure that the best access solution is achieved to enable efficient and safe approach to the aircraft.

Features such as lighting, tool shelves, cable runs, hose attachments, earth bonding and compressed air points are all added features that can be incorporated into the aviation access systems.

Aircraft maintenance platforms look to eliminate the risk of falls and injury by assessing the hazards and designing an aircraft access system with the appropriate risk controls whilst ensuring efficient use for the operators.

Clear work areas and ease of use are key considerations in the design of aircraft maintenance platforms.

Airbus Advanced Manufacturing Research Centre in Broughton is part of their ‘Wings of Tomorrow’ research and technology programme, working on the creation of new prototype aeroplane wings, with the goal of making aviation as a whole, more sustainable. To do this, they needed a way to safely access the trailing edge of their wing cover. The solution to their problem was a cantilevered (vertical support fastened at one end) aircraft access system to fit over the main assembly jig.

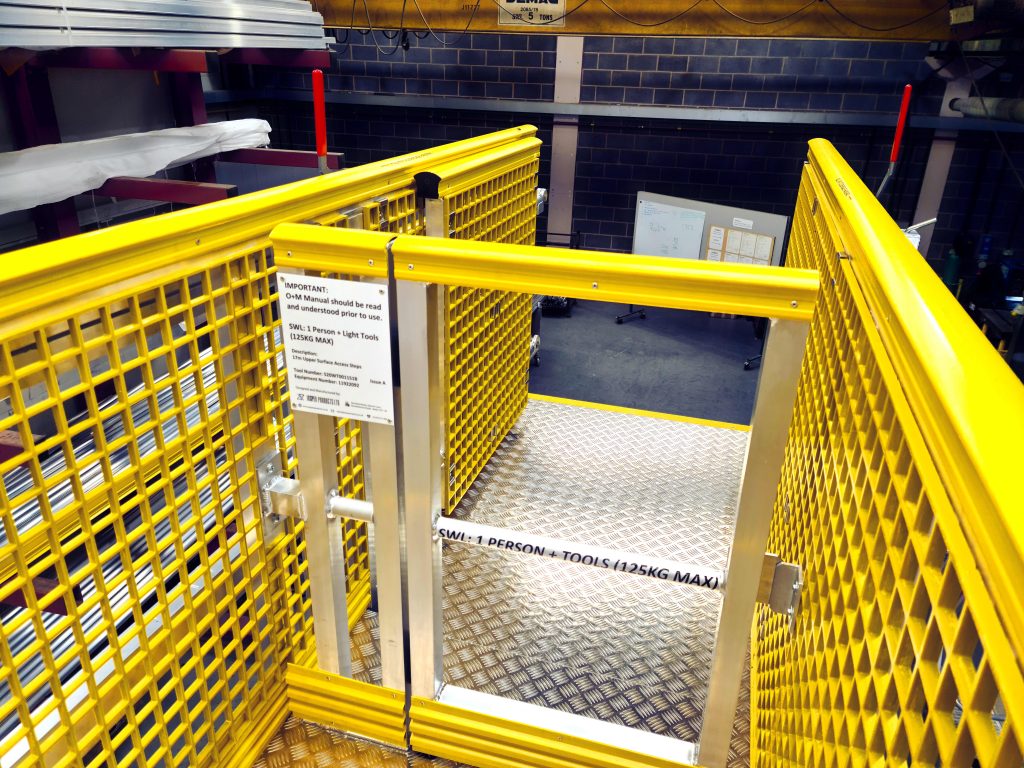

Airbus operatives would need to perform inspections and to carry out drilling and fastening procedures. The aircraft access step as designed by Jasper Products makes all of this easy, with 1200mm extendable handrails to keep staff safe while working out on the wing.

Another consideration made to the safety of Airbus employees was the implementation of GRP (glass re-enforced plastic) mesh secured to both the platform area and the extendable handrails. The mesh eliminates the risk of anyone’s hands becoming trapped in the apparatus.

The platform is designed to be easily movable, and to be positioned at any point along the trailing edge of the wing as needed. As such, the handrails themselves are simple to adjustable and manually operated, allowing workers to adapt the platform to comfortably suit any configuration they should require.

Jasper Products is proud to play a part in providing aircraft access solutions whilst facilitating work for a more sustainable future.